|

|

Post by candyman on Mar 14, 2010 11:42:27 GMT -5

|

|

|

|

Post by Nyonk on Mar 14, 2010 11:55:34 GMT -5

amazing.... keep updating bro.. i like it

|

|

|

|

Post by coldiron on Mar 14, 2010 13:08:46 GMT -5

Those legs are awesome, great work.

|

|

|

|

Post by magengar on Mar 14, 2010 14:03:12 GMT -5

Hey Candyman, Welcome to RJ! And that's some serious eye-candy ya got goin on there, too! Keep it up, can't wait to see the finished custom, it looks awesome!!!  zozo-Magengar |

|

|

|

Post by darksenshi on Mar 14, 2010 14:17:53 GMT -5

Wow! Thats going to be truly awesome. Keep us updated!

|

|

|

|

Post by mazingerzetto on Mar 14, 2010 17:40:28 GMT -5

it's awesome !!!!!

great artwork!!!!!

|

|

|

|

Post by candyman on Mar 14, 2010 17:48:36 GMT -5

|

|

|

|

Post by snowdog on Mar 15, 2010 0:24:24 GMT -5

Welcome Candyman! Glad that you decided to join. Great pics, as usual. Keep them coming!!

|

|

|

|

Post by magengar on Mar 15, 2010 9:43:29 GMT -5

Man, the detail and machining looks friggin Amazing; I gotta Bow to you, your work ROCKS!  zozo-magengar |

|

|

|

Post by candyman on Mar 17, 2010 12:33:40 GMT -5

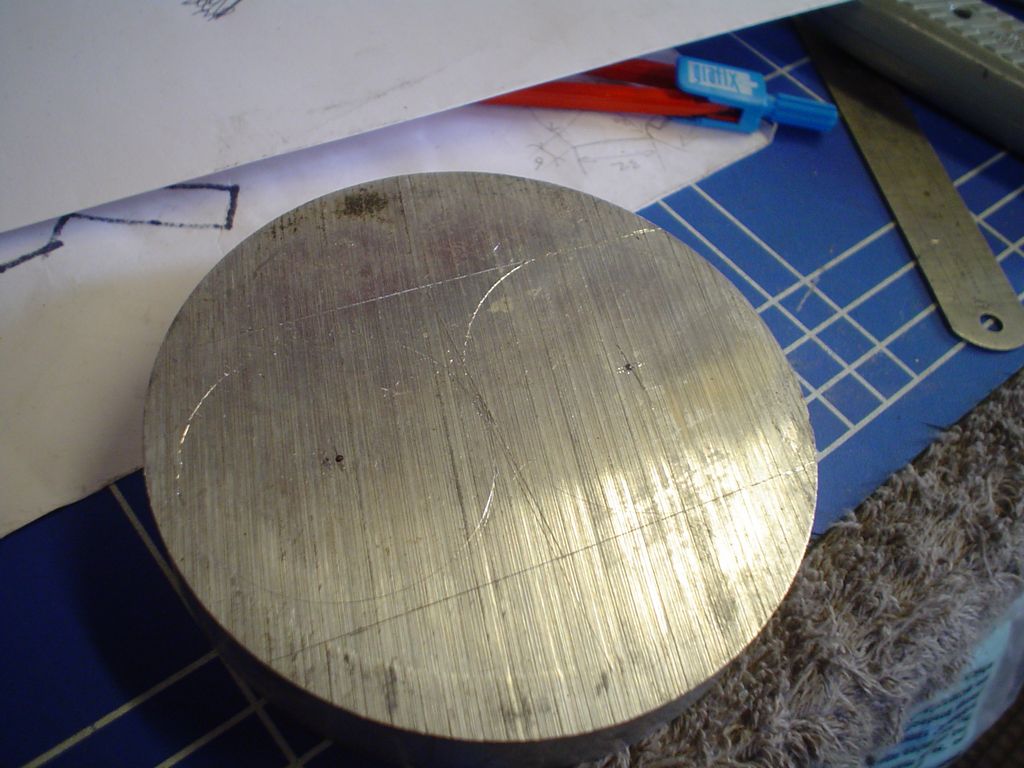

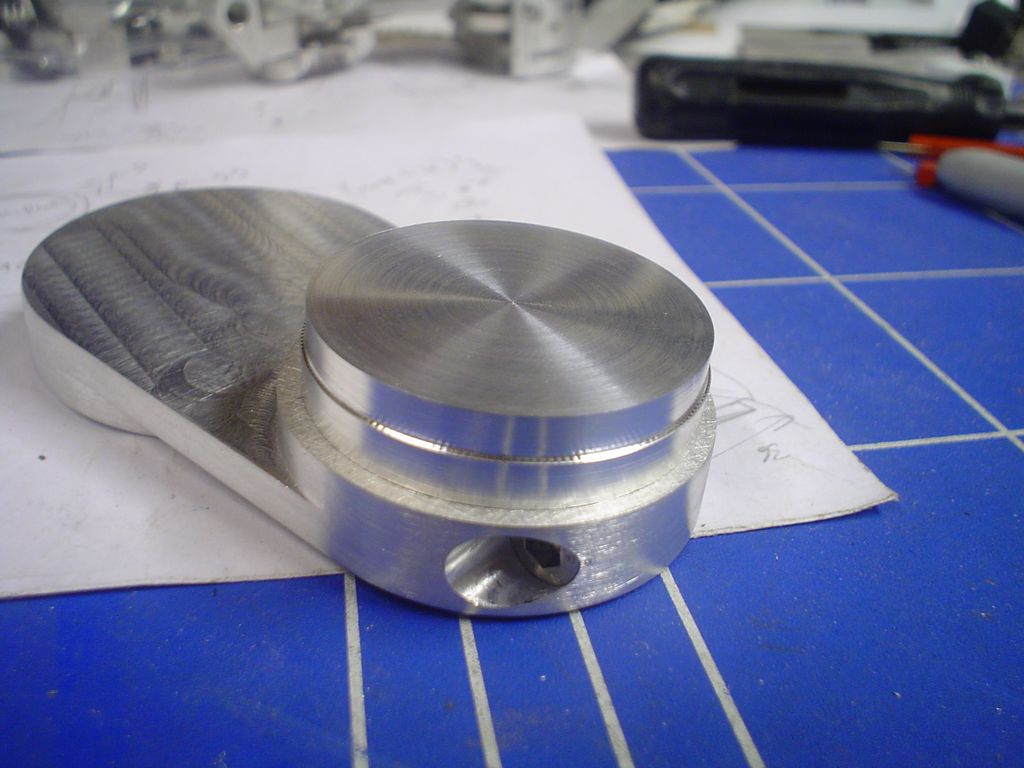

Got hold of 2 pieces of 15mm thick for where the thigh joins the hip.  my woefully small rotary table is under here somewhere!  cut down 5mm both sides to make the circles then trimmed off the excess  all smoothed out  sinking the holes in the sides  like so  |

|

|

|

Post by droutmaster on Mar 17, 2010 13:35:15 GMT -5

wow that is a project, i cant wait to see it complete =D

|

|

|

|

Post by candyman on Mar 20, 2010 15:38:21 GMT -5

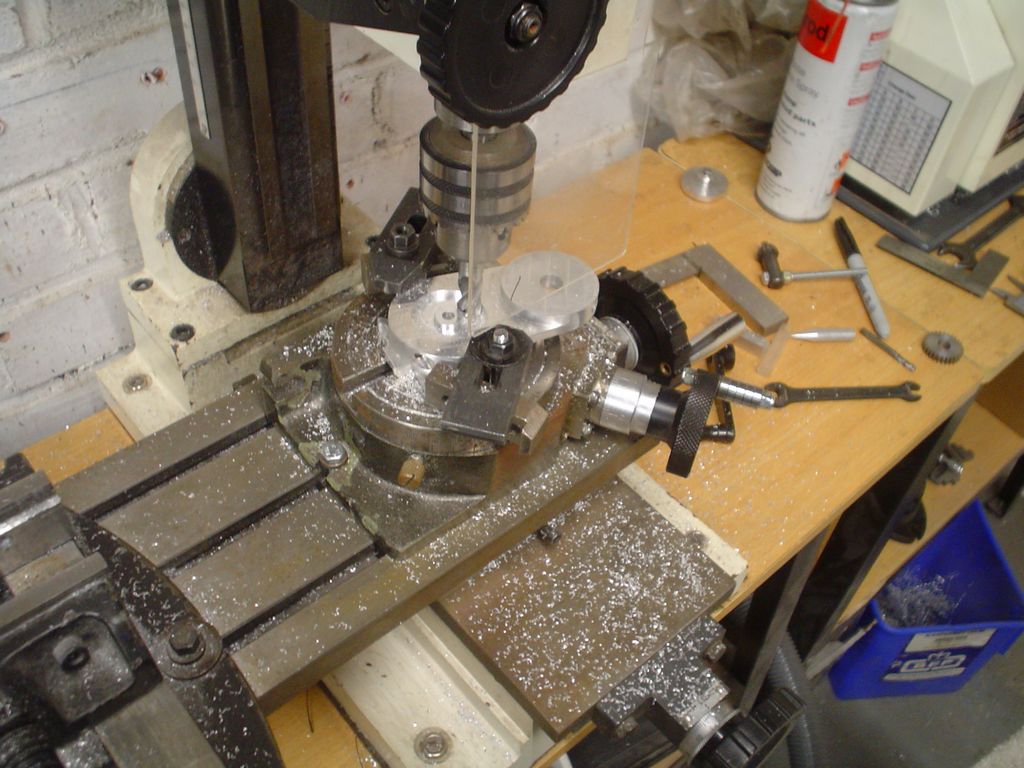

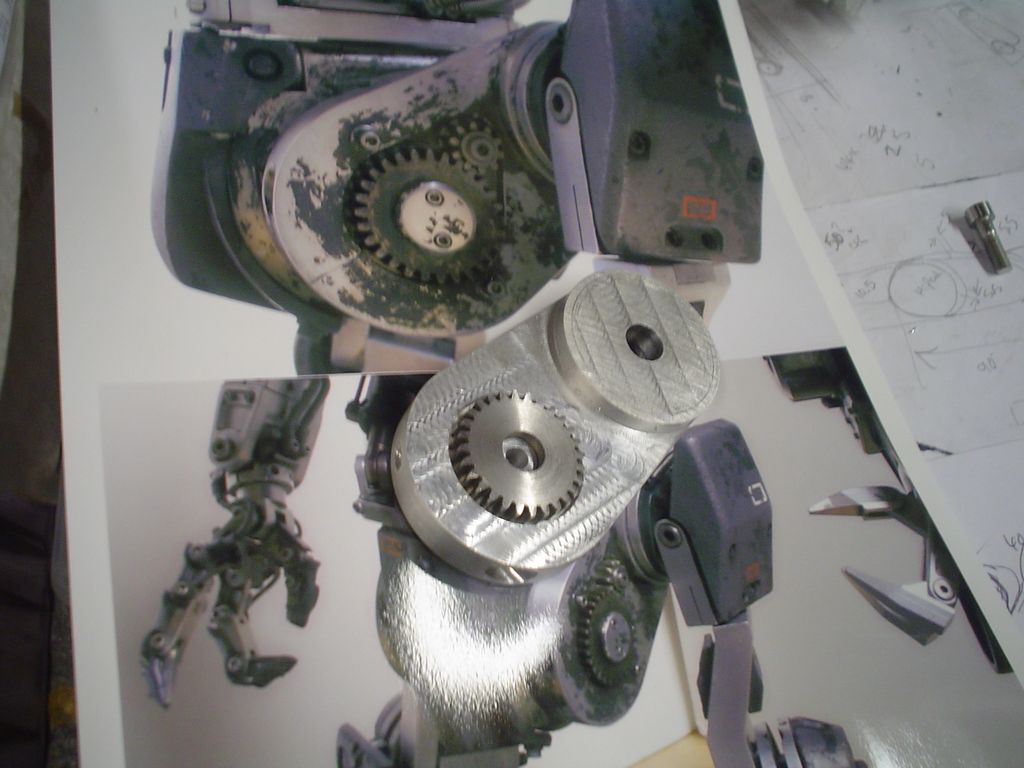

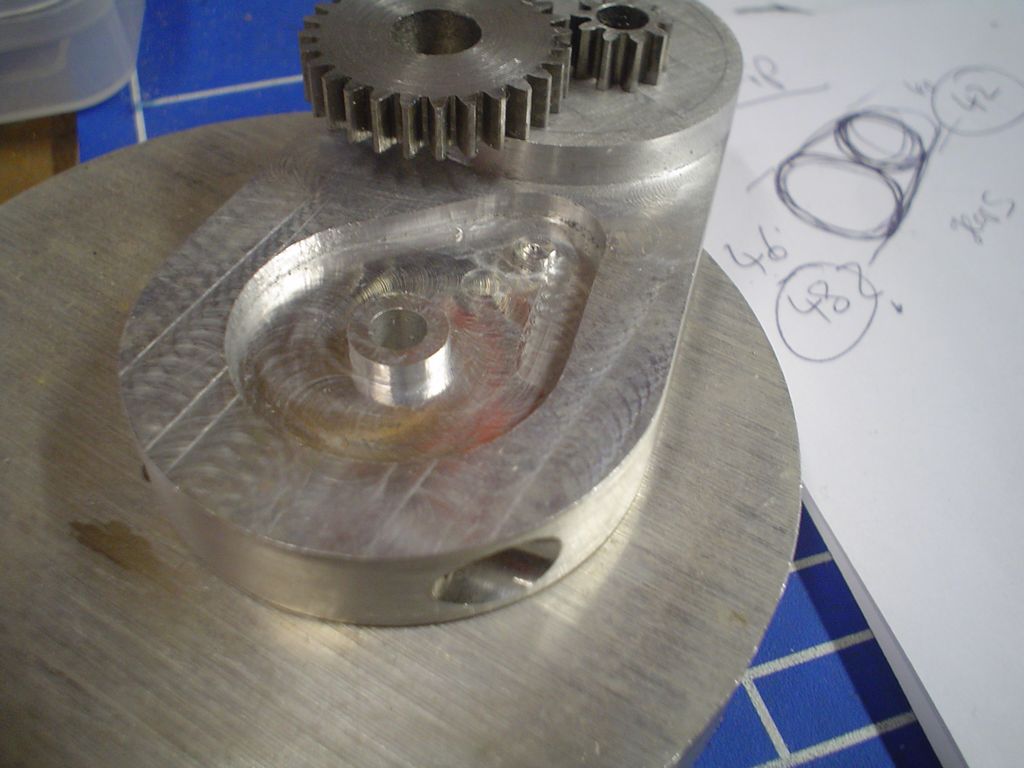

turned this lovely piece  then cut a slant on 50% of it, only a few degrees  Now the gears in the pic I cant copy exactly as this is a different scale, so I had to measure the gears in the pic and then count the teeth. The spec is written bottom right in that pic, to achive that tooth count and that overall diamete the gears quite conveniently needed to be Mod 1 pitch. So I bought a wide 28t, mod 1 gear that I can cut in half and use both sides.  next the recess needs to be cut, so back on the rotary table. you can see the gear cut in half on the right.  and that goes something like that  |

|

|

|

Post by droutmaster on Mar 20, 2010 21:28:46 GMT -5

dude, if you finish this figure you will be a true king o custom figures hands down.

how tall this figure will be when its done, or course if you have an idea.

|

|

|

|

Post by mechamasterj on Mar 21, 2010 10:43:56 GMT -5

holy smokes bat man..... this is one major and awesome project you are undertaking!! Cant wait to see more!

|

|

|

|

Post by magengar on Mar 21, 2010 12:36:04 GMT -5

I'm speechless... wish I had access to such tools. And I wish I had the brains for that kind of math. And I wish I had my own small warehouse space to do this kind of stuff with all those material resources. This is truly Amazing; labeling you the "King of Customs" would be an understatement. Rock On!  zozo-Magengar |

|

|

|

Post by repairtechjon on Mar 21, 2010 13:26:09 GMT -5

Great work candyman! Thanks for joining and sharing this great project with us. It's great to see the fruit of your own efforts.

Do you work in toy prototyping/modeling for a film prop shop? Or just doing this after hours for fun?

|

|

|

|

Post by candyman on Mar 23, 2010 13:30:16 GMT -5

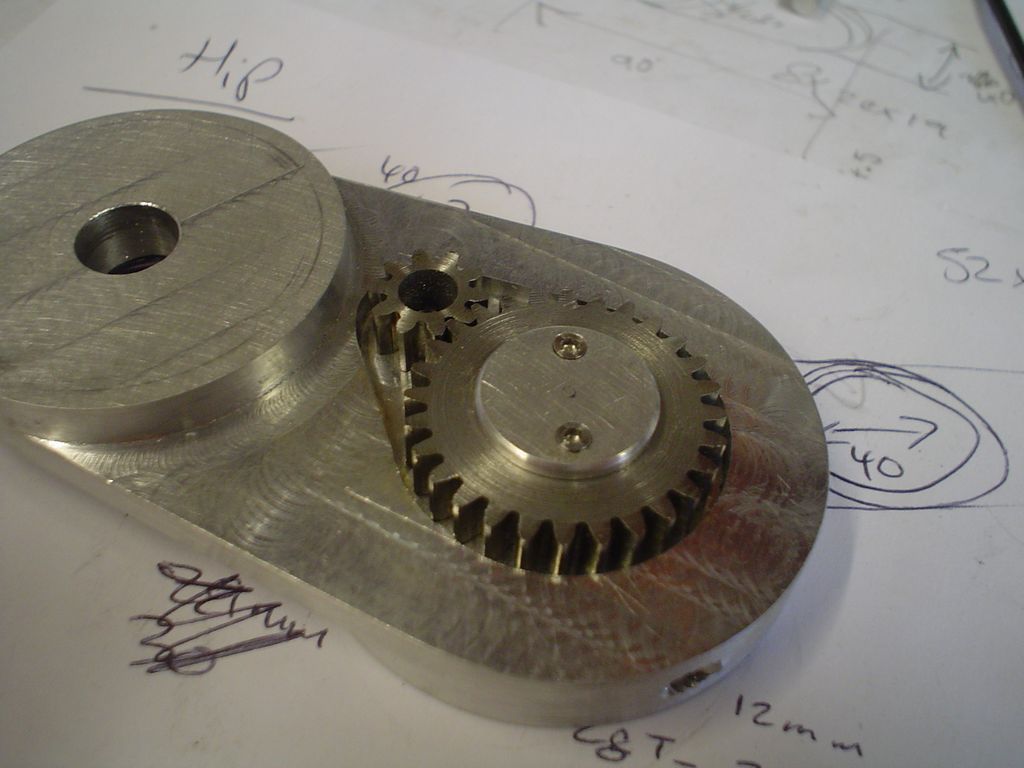

thanks for the support! No for a job i work with computers in an ID card company, this is just somehting I work on at home in my garage  im waiting on a pair of little 10 tooth gears to arrive form "technobots" good website for bits and pieces (google it). for now im fitting it up with an old pinion from one of my trucks  some careful machining required here  all in place and made a little plate for the main gear, had to turn some M2 screws down a bit as they were too big!  then made a block, fitted it to one of the hip joints and attached the top of the leg.  |

|

|

|

Post by xiombarg on Mar 23, 2010 14:06:47 GMT -5

You're a wild man! Way to take on a serious project and run with it. I personally love to do big projects, but what you're doing is way more hardcore than anything I do. Keep it up!

|

|

|

|

Post by candyman on Mar 28, 2010 11:31:48 GMT -5

Made 2 more little fittings, getting the hang of these now, 2 small pieces of rod, drill one 2mm and bevel the end, hold against the 2nd mark wher the hole is drill 1.7 tap M2, then drill through 2mm and counter the top 3.5 then add M2 hardware, everyone with me? no? good......  Me looking grumpy  milled a recess both sides then drill and tap to attach the aforementioned fittings.  got the plastic gears I said about  all fitted together, starting to look like a leg, made a plastic capping to sit on the joint behind the ..... thing....... you know what I mean, its been a long day.  |

|

|

|

Post by admin1 aka Ed on Mar 28, 2010 12:32:46 GMT -5

-Love the work! I imagine your garage is pretty darned big, because you are using some great CNC machines, right? LOL

Thanks for sharing because the work is so inspiring.

E

|

|